Våra fjädrar är tillverkade för att uppfylla exakta specifikationer, säkerställer överlägsen prestanda och tillförlitlighet.

Från rostfritt stål till specialiserade legeringar, vi arbetar med en mängd olika material för att möta dina krav.

Oavsett om du behöver tryckfjädrar, torsionsfjädrar, förlängningsfjädrar, eller trådformer, vi levererar skräddarsydda lösningar.

Direkt fabriksprissättning säkerställer att du får det bästa värdet för högsta kvalitet.

Strömlinjeformade processer gör att vi kan leverera dina beställningar i tid, varje gång.

We efficiently handle international logistics to deliver anywhere in the world.

Springs are the unsung heroes in many industries, providing the flexibility, strength, and precision needed for countless applications. Whether you’re designing high-performance machinery or everyday tools, selecting the right material ensures reliability, varaktighet, and cost-effectiveness. Let’s break down the essentials to help you make an informed decision!

Spring steels are incredibly popular due to their combination of elasticity, tensile strength, and fatigue resistance. They’re ideal for applications where springs are under constant stress or load.

Om din applikation innebär exponering för fukt, kemikalier, eller extremt väder, rostfritt stål är ditt bästa material. Dessa legeringar är resistenta mot rost och säkerställer långvarig prestanda.

Ibland, din ansökan kräver något extra. Det är där specialmaterial som superlegeringar och höghållfasta kompositer kommer in.

Case 1: Marine Equipment Manufacturer

A client designing springs for deep-sea applications chose 316L stainless steel for its superior resistance to saltwater corrosion. This decision doubled the service life of their products and reduced maintenance costs by 30%.

Case 2: Heavy Machinery Builder

A manufacturer of industrial presses switched to SWP alloy steel for their tension springs. The result? Springs withstood 20% higher loads and lasted 50% longer under continuous operation.

Case 3: Food Processing Startup

For springs in food slicers, 304 rostfritt stål was the perfect choice due to its affordability and compliance with food safety standards. Uppstarten sparad 15% på kostnader samtidigt som hygienisk prestanda säkerställs.

| Serienr. | Stålkvalitet | C (%) | Och (%) | Mn (%) | Cr (%) | Mo (%) | V (%) | B (%) | I (%) | Cu (%) | P (%) | S (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 65 | 0.62–0,70 | 0.17–0,37 | 0.50–0,80 | ≤ 0.25 | — | — | — | 0.25 | 0.25 | ≤ 0.035 | ≤ 0.035 |

| 2 | 70 | 0.62–0,75 | 0.17–0,37 | 0.50–0,80 | ≤ 0.25 | — | — | — | 0.25 | 0.25 | ≤ 0.035 | ≤ 0.035 |

| 3 | 85 | 0.72–0,85 | 0.17–0,37 | 0.50–0,80 | ≤ 0.25 | — | — | — | 0.25 | 0.25 | ≤ 0.035 | ≤ 0.035 |

| 4 | 65Mn | 0.62–0,70 | 0.17–0,37 | 0.90–1.20 | ≤ 0.25 | — | — | — | 0.25 | 0.25 | ≤ 0.035 | ≤ 0.035 |

| 5 | 55Si2Mn | 0.52–0,60 | 1.50–2.00 | 0.60–0,90 | ≤ 0.35 | — | — | — | 0.35 | 0.35 | ≤ 0.035 | ≤ 0.035 |

| 6 | 55Si2MnB | 0.52–0,60 | 1.50–2.00 | 0.60–0,90 | ≤ 0.35 | — | — | 0.0005–0,004 | 0.35 | 0.35 | ≤ 0.035 | ≤ 0.035 |

| 7 | 55Si2Mn ETC | 0.52–0,60 | 0.70–1.00 | 1.00–1.30 | ≤ 0.35 | — | 0.08–0,16 | 0.0005–0,0035 | 0.35 | 0.35 | ≤ 0.035 | ≤ 0.035 |

| 8 | 60Si2Mn | 0.56–0,64 | 1.50–2.00 | 0.60–0,90 | ≤ 0.35 | — | — | — | 0.35 | 0.35 | ≤ 0.035 | ≤ 0.035 |

| 9 | 60Si2MnA | 0.56–0,64 | 1.60–2.00 | 0.60–0,90 | ≤ 0.35 | — | — | — | 0.35 | 0.35 | ≤ 0.035 | ≤ 0.030 |

| 10 | 60Si2CrA | 0.56–0,64 | 1.40–1,80 | 0.40–0,70 | 0.70–1.00 | — | — | — | 0.25 | 0.25 | ≤ 0.035 | ≤ 0.030 |

| 11 | 55Mask | 0.56–0,64 | 1.40–1,80 | 0.40–0,70 | 0.90–1.20 | — | 0.10–0,20 | — | 0.25 | 0.25 | ≤ 0.035 | ≤ 0.035 |

| 12 | 60CrMnA | 0.56–0,64 | 0.17–0,37 | 0.70–1.00 | 0.70–1.00 | — | — | — | 0.25 | 0.35 | ≤ 0.035 | ≤ 0.035 |

| 13 | 50Mask | 0.46–0,54 | 0.17–0,37 | 0.50–0,80 | 0.80–1.10 | — | 0.10–0,20 | — | 0.25 | 0.25 | ≤ 0.035 | ≤ 0.035 |

| 14 | 30CrV2A | 0.26–0,34 | 0.17–0,37 | ≤ 0.40 | 2.00–2,50 | — | 0.50–0,80 | 4.4–5,0 | 0.35 | 0.35 | ≤ 0.035 | ≤ 0.035 |

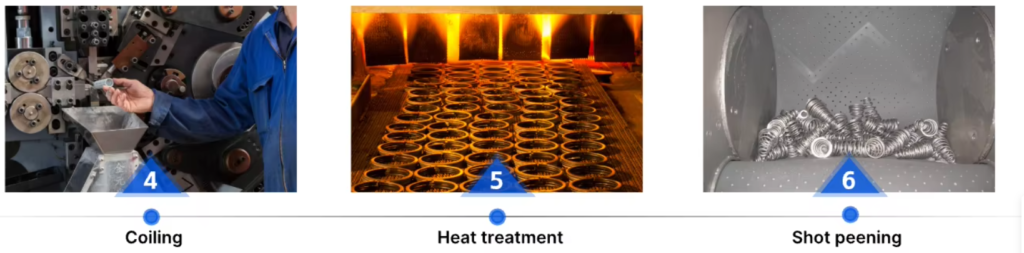

Spring heat treatment is essential for optimizing mechanical properties, ensuring durability, and enhancing fatigue resistance. Various strengthening techniques, such as quenching, tempering, and surface treatments, are applied based on material type and application requirements.

The heat treatment process for springs can be categorized into three types:

The quenching process ensures uniform martensitic transformation, followed by tempering to relieve stress and enhance toughness. Techniques such as isothermal tempering further improve plasticity and toughness, ensuring the spring maintains dimensional accuracy and mechanical stability.

| Process Type | Beskrivning | Materials Used | Key Effects |

|---|---|---|---|

| Quenching & Tempering | Heating above Ac3, holding, then rapid cooling and tempering. | High-carbon steel, legerat stål | Increases strength, hardness, and elasticity. |

| Cold Work Strengthening | Uses mechanical deformation instead of heat treatment. | Stainless steel wire, cold-rolled steel strips | Enhances work-hardening properties. |

| Aging Treatment | Additional heat stabilization after initial processing. | Certain alloy materials | Improves stability and strength. |

| Isothermal Quenching | Maintains temperature above Ms, cools in molten salt. | High-carbon steel, alloy springs | Enhances toughness and plasticity. |

| Controlled Tempering | Gradual cooling to prevent deformation. | Precision springs, mechanical components | Reduces internal stress and ensures accuracy. |

This structured approach ensures that each heat treatment method is aligned with specific material properties and application requirements for optimized performance.

The heat treatment of springs:

| Method | Process Description | Key Benefits | Common Applications |

|---|---|---|---|

| Conventional Heat Treatment | Heating and cooling steel to adjust mechanical properties | Increases strength, elasticity, and durability | Medium to high-carbon steel springs |

| Surface Hardening Treatment | Carburizing, nitriding, or induction hardening of the outer layer | Enhances wear resistance while keeping core toughness | Automotive and industrial springs |

| Aging & Tempering | Heat treatment to relieve internal stresses and refine microstructure | Improves stability and mechanical consistency | Precision and high-load springs |

| Stålkvalitet | Austenitizing Temperature (°C) | Isothermal Quenching Temperature (°C) | Cooling Time (min) | Hardness (HRC) |

|---|---|---|---|---|

| 65 | 820 ± 10 | 320 – 340 | 15 – 20 | 46 – 48 |

| 60Si2MnA | 870 ± 10 | 260 | 20 – 25 | 50 – 52 |

| 50Mask | 850 ± 10 | 300 | 20 – 25 | 55 – 57 |

| Steel Type | Heat Treatment Process | Hardness (HRC) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Impact Toughness (J/cm²) |

|---|---|---|---|---|---|---|

| 50Mask | Conventional Quenching + Tempering | 48 | 1750 | 1500 | 10 | 44 |

| 60Si2MnA | Isothermal Quenching + Tempering | 47 | 1900 | 1750 | 11 | 46 |

| 65Si2MnWA | Isothermal Quenching + Tempering | 50 | 2100 | 1980 | 9 | 43 |

This table format provides a clear and organized comparison of different heat treatment techniques for springs.

Xiamen Linspring was able to manufacture my custom order to specifications and was helpful and communicatie along the way.The quality of the delivered product was good.

This was my second order with Linspring. The seller is great to communicate with and the spring were perfect,just like the first order. Thank you for your prompt,courteous.

Very happy with our custom springs. On time and shipping was fast

Springs are essential components in countless industries, from automotive and aerospace to medical devices and household appliances. Custom springs, in particular, offer tailored solutions to meet specific requirements for performance, size, material, and application. Designing a custom spring requires careful consideration of numerous factors, from functionality to environmental conditions.

Kompressionsfjädrar

Tension Springs

Torsionsfjädrar

Flat Springs

Specialty Springs

Choosing the right material is critical for the performance and durability of a custom spring. Some common materials include:

Carbon Steel

Rostfritt stål

Alloy Steel

Phosphor Bronze and Beryllium Copper

Titanium

Inconel and Other Superalloys

When designing a custom spring, there are several factors to consider:

Typ fjäder: Choose the appropriate spring type (compression, tension, etc.) based on the application.

Belastningskrav:

Spring Dimensions:

Material Selection: Choose a material that meets the application’s environmental, strength, and durability requirements.

Stress and Fatigue:

Operating Environment:

End Type:

Manufacturing Constraints:

Define Your Requirements:

Choose a Material:

Work with LINSPRING:

Prototype Development:

Final Production:

Provide Clear Specifications:

Request Samples:

Discuss Compliance:

Leverage Expertise:

Plan for Scalability:

Custom springs are a game-changer for applications that demand precision, performance, and reliability. By carefully considering factors like material, design, and operating environment, you can create a spring that perfectly suits your needs. Partnering with a trusted manufacturer LIKE LINSPRING ensures a seamless process from design to production, helping you achieve optimal results.

Still unsure which material fits your needs? Let’s discuss your specific application. Whether it’s automotive, aerospace, or precision engineering, we can help you select the perfect material tailored to your requirements.

Would you like a tailored recommendation or a deeper dive into one of the materials? Let’s make your project a success!

E-post: sales@linspring.net

Telefon:+86-13599531763

Adress: Enhet 502, golv 5, Byggnad B, # 1 verkstad, Bilindustrin City Parts Supporting Center (fas iv), Guankou stad, Jimei-distriktet, Xiamen,Fujian,Kina

Vi kommer att kontakta dig inom 1 arbetsdag.