Nossas molas são fabricadas para atender às especificações exatas, garantindo desempenho e confiabilidade superiores.

Do aço inoxidável às ligas especializadas, trabalhamos com uma variedade de materiais para atender às suas necessidades.

Se você precisa de molas de compressão, molas de torção, molas de extensão, ou formas de arame, entregamos soluções personalizadas.

O preço direto da fábrica garante que você obtenha o melhor valor pela qualidade de alto nível.

Processos simplificados nos permitem entregar seus pedidos no prazo, toda vez.

Lidamos com eficiência com a logística internacional para entregar em qualquer lugar do mundo.

As molas são os heróis anônimos em muitos setores, proporcionando a flexibilidade, força, e precisão necessária para inúmeras aplicações. Esteja você projetando máquinas de alto desempenho ou ferramentas de uso diário, selecionar o material certo garante confiabilidade, durabilidade, e custo-benefício. Vamos detalhar o essencial para ajudá-lo a tomar uma decisão informada!

Os aços para molas são incrivelmente populares devido à sua combinação de elasticidade, resistência à tracção, e resistência à fadiga. Eles são ideais para aplicações onde as molas estão sob tensão ou carga constante.

Se o seu aplicativo envolve a exposição à umidade, produtos químicos, ou clima extremo, aço inoxidável é o seu material preferido. Essas ligas são resistentes à ferrugem e garantem um desempenho duradouro.

Às vezes, Seu aplicativo exige algo extra. É aí que materiais especiais, como super-operadores e compósitos de alta resistência, entram.

Caso 1: Fabricante de equipamentos marítimos

Um cliente que projetava molas para aplicações em alto mar escolheu 316L aço inoxidável por sua resistência superior à corrosão da água salgada. Esta decisão duplicou a vida útil dos seus produtos e reduziu os custos de manutenção em 30%.

Caso 2: Construtor de máquinas pesadas

Um fabricante de prensas industriais mudou para Liga de aço SWP por suas molas de tensão. O resultado? As molas resistiram 20% cargas mais altas e duraram 50% mais tempo sob operação contínua.

Caso 3: Startup de processamento de alimentos

Para molas em fatiadores de alimentos, 304 aço inoxidável foi a escolha perfeita devido ao seu preço acessível e conformidade com as normas de segurança alimentar. A inicialização salva 15% nos custos, garantindo ao mesmo tempo um desempenho higiénico.

| Número de série. | Classe de aço | C (%) | E (%) | Mn (%) | Cr (%) | Mo (%) | V (%) | B (%) | Em (%) | Cu (%) | P (%) | S (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 65 | 0.62–0,70 | 0.17–0,37 | 0.50–0,80 | ≤ 0.25 | - | - | - | 0.25 | 0.25 | ≤ 0.035 | ≤ 0.035 |

| 2 | 70 | 0.62–0,75 | 0.17–0,37 | 0.50–0,80 | ≤ 0.25 | - | - | - | 0.25 | 0.25 | ≤ 0.035 | ≤ 0.035 |

| 3 | 85 | 0.72–0,85 | 0.17–0,37 | 0.50–0,80 | ≤ 0.25 | - | - | - | 0.25 | 0.25 | ≤ 0.035 | ≤ 0.035 |

| 4 | 65Mn | 0.62–0,70 | 0.17–0,37 | 0.90–1,20 | ≤ 0.25 | - | - | - | 0.25 | 0.25 | ≤ 0.035 | ≤ 0.035 |

| 5 | 55Si2Mn | 0.52–0,60 | 1.50–2h00 | 0.60–0,90 | ≤ 0.35 | - | - | - | 0.35 | 0.35 | ≤ 0.035 | ≤ 0.035 |

| 6 | 55Si2MnB | 0.52–0,60 | 1.50–2h00 | 0.60–0,90 | ≤ 0.35 | - | - | 0.0005–0,004 | 0.35 | 0.35 | ≤ 0.035 | ≤ 0.035 |

| 7 | 55Si2Mn ETC | 0.52–0,60 | 0.70–1,00 | 1.00–1h30 | ≤ 0.35 | - | 0.08–0,16 | 0.0005–0,0035 | 0.35 | 0.35 | ≤ 0.035 | ≤ 0.035 |

| 8 | 60Si2Mn | 0.56–0,64 | 1.50–2h00 | 0.60–0,90 | ≤ 0.35 | - | - | - | 0.35 | 0.35 | ≤ 0.035 | ≤ 0.035 |

| 9 | 60Si2MnA | 0.56–0,64 | 1.60–2h00 | 0.60–0,90 | ≤ 0.35 | - | - | - | 0.35 | 0.35 | ≤ 0.035 | ≤ 0.030 |

| 10 | 60Si2CrA | 0.56–0,64 | 1.40–1,80 | 0.40–0,70 | 0.70–1,00 | - | - | - | 0.25 | 0.25 | ≤ 0.035 | ≤ 0.030 |

| 11 | 55Minhoca | 0.56–0,64 | 1.40–1,80 | 0.40–0,70 | 0.90–1,20 | - | 0.10–0,20 | - | 0.25 | 0.25 | ≤ 0.035 | ≤ 0.035 |

| 12 | 60CrMnA | 0.56–0,64 | 0.17–0,37 | 0.70–1,00 | 0.70–1,00 | - | - | - | 0.25 | 0.35 | ≤ 0.035 | ≤ 0.035 |

| 13 | 50Minhoca | 0.46–0,54 | 0.17–0,37 | 0.50–0,80 | 0.80–1,10 | - | 0.10–0,20 | - | 0.25 | 0.25 | ≤ 0.035 | ≤ 0.035 |

| 14 | 30CrV2A | 0.26–0,34 | 0.17–0,37 | ≤ 0.40 | 2.00–2,50 | - | 0.50–0,80 | 4.4–5,0 | 0.35 | 0.35 | ≤ 0.035 | ≤ 0.035 |

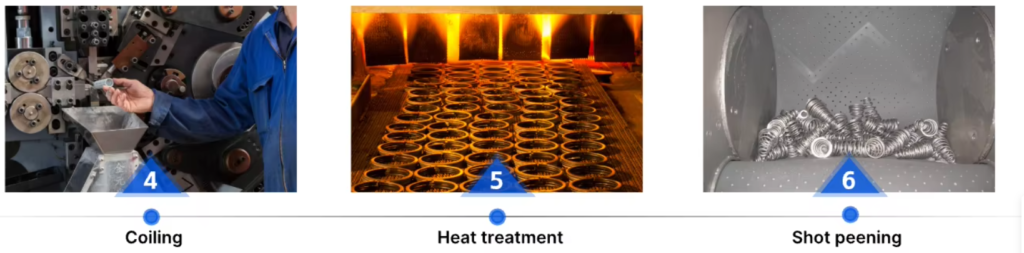

O tratamento térmico de primavera é essencial para otimizar as propriedades mecânicas, garantindo durabilidade, e aumentando a resistência à fadiga. Várias técnicas de fortalecimento, como extinção, têmpera, e tratamentos de superfície, são aplicados com base no tipo de material e requisitos de aplicação.

O processo de tratamento térmico para molas pode ser categorizado em três tipos:

O processo de têmpera garante transformação martensítica uniforme, seguido de têmpera para aliviar o estresse e aumentar a resistência. Técnicas como o tempeamento isotérmico melhoram ainda mais a plasticidade e a resistência, Garantir a mola mantém precisão dimensional e estabilidade mecânica.

| Tipo de processo | Descrição | Materiais utilizados | Efeitos -chave |

|---|---|---|---|

| Tireização & Temering | Aquecimento acima de AC3, contenção, Então o resfriamento rápido e a temperatura. | Aço de alto carbono, liga de aço | Aumenta a força, dureza, e elasticidade. |

| Fortalecimento do Trabalho a Frio | Usa deformação mecânica em vez de tratamento térmico. | Fio de aço inoxidável, Tiras de aço com laminação a frio | Aprimora as propriedades de endurecimento do trabalho. |

| Tratamento de envelhecimento | Estabilização adicional de calor após processamento inicial. | Certos materiais de liga | Melhora a estabilidade e a força. |

| Extinção isotérmica | Mantém a temperatura acima da ms, esfria em sal fundido. | Aço de alto carbono, Springs de liga | Aumenta a resistência e a plasticidade. |

| Temperamento controlado | Resfriamento gradual para evitar a deformação. | Molas de precisão, componentes mecânicos | Reduz o estresse interno e garante precisão. |

Esta abordagem estruturada garante que cada método de tratamento térmico esteja alinhado com propriedades específicas do material e requisitos de aplicação para desempenho otimizado.

O tratamento térmico de molas:

| Método | Descrição do Processo | Principais benefícios | Aplicações comuns |

|---|---|---|---|

| Tratamento Térmico Convencional | Aquecimento e resfriamento de aço para ajustar propriedades mecânicas | Aumenta a força, elasticidade, e durabilidade | Molas de aço de médio a alto carbono |

| Tratamento de endurecimento de superfície | Carburização, nitretação, ou endurecimento por indução da camada externa | Melhora a resistência ao desgaste, mantendo a tenacidade do núcleo | Molas automotivas e industriais |

| Envelhecimento & Temering | Tratamento térmico para aliviar tensões internas e refinar a microestrutura | Melhora a estabilidade e consistência mecânica | Molas de precisão e alta carga |

| Classe de aço | Temperatura de Austenitização (°C) | Temperatura de têmpera isotérmica (°C) | Tempo de resfriamento (min) | Dureza (CDH) |

|---|---|---|---|---|

| 65 | 820 ± 10 | 320 – 340 | 15 – 20 | 46 – 48 |

| 60Si2MnA | 870 ± 10 | 260 | 20 – 25 | 50 – 52 |

| 50Minhoca | 850 ± 10 | 300 | 20 – 25 | 55 – 57 |

| Tipo de aço | Processo de tratamento térmico | Dureza (CDH) | Resistência à tracção (MPa) | Força de rendimento (MPa) | Alongamento (%) | Resistência ao Impacto (J/cm²) |

|---|---|---|---|---|---|---|

| 50Minhoca | Têmpera Convencional + Temering | 48 | 1750 | 1500 | 10 | 44 |

| 60Si2MnA | Extinção isotérmica + Temering | 47 | 1900 | 1750 | 11 | 46 |

| 65Si2MnWA | Extinção isotérmica + Temering | 50 | 2100 | 1980 | 9 | 43 |

Este formato de tabela fornece uma comparação clara e organizada de diferentes técnicas de tratamento térmico para molas.

Xiamen Linspring foi capaz de fabricar meu pedido personalizado de acordo com as especificações e foi útil e comunicativo ao longo do caminho..

Este foi meu segundo pedido com Linspring. O vendedor é ótimo para se comunicar e a primavera foi perfeita,assim como o primeiro pedido. Obrigado pela sua indicação,cortês.

Muito feliz com nossas molas personalizadas. No prazo e a entrega foi rápida

As molas são componentes essenciais em inúmeras indústrias, desde automotivo e aeroespacial até dispositivos médicos e eletrodomésticos. Molas personalizadas, em particular, oferecer soluções personalizadas para atender a requisitos específicos de desempenho, tamanho, material, e aplicação. Projetar uma mola personalizada requer consideração cuidadosa de vários fatores, da funcionalidade às condições ambientais.

Molas de compressão

Molas de tensão

Molas de torção

Molas planas

Molas Especiais

Escolher o material certo é fundamental para o desempenho e durabilidade de uma mola personalizada. Alguns materiais comuns incluem:

Aço carbono

Aço inoxidável

Liga de aço

Bronze Fósforo e Cobre Berílio

Titânio

Inconel e outras superligas

Ao projetar uma mola personalizada, há vários fatores a serem considerados:

Tipo de mola: Escolha o tipo de mola apropriado (compressão, tensão, etc.) com base na aplicação.

Requisitos de carga:

Dimensões da Primavera:

Seleção de Materiais: Escolha um material que atenda às exigências ambientais da aplicação, força, e requisitos de durabilidade.

Estresse e fadiga:

Ambiente Operacional:

Tipo final:

Restrições de fabricação:

Defina seus requisitos:

Escolha um material:

Trabalhe com LINSPRING:

Desenvolvimento de protótipo:

Produção Final:

Forneça especificações claras:

Solicitar Amostras:

Discutir conformidade:

Aproveite a experiência:

Planeje a escalabilidade:

Molas personalizadas são uma virada de jogo para aplicações que exigem precisão, desempenho, e confiabilidade. Considerando cuidadosamente fatores como material, projeto, e ambiente operacional, você pode criar uma mola que atenda perfeitamente às suas necessidades. A parceria com um fabricante confiável LIKE LINSPRING garante um processo contínuo desde o design até a produção, ajudando você a alcançar os melhores resultados.

Ainda não tenho certeza de qual material atende às suas necessidades? Vamos discutir sua aplicação específica. Seja automotivo, aeroespacial, ou engenharia de precisão, podemos ajudá-lo a selecionar o material perfeito adaptado às suas necessidades.

Gostaria de uma recomendação personalizada ou um mergulho mais profundo em um dos materiais? Vamos fazer do seu projeto um sucesso!

E-mail: sales@linspring.net

Telefone:+86-13599531763

Endereço: Unidade 502, chão 5, Edifício B, # 1 oficina, Centro de Apoio a Peças da Indústria Automobilística (fase IV), Cidade de Guankou, Distrito de Jimei, Xiamen,Fujian,China

Entraremos em contato com você dentro 1 dia útil.