Jousemme on muotoiltu vastaamaan tarkkoja eritelmiä, varmistaa erinomainen suorituskyky ja luotettavuus.

Ruostumattomasta teräksestä erikoistuneisiin seoksiin, Työskentelemme useiden materiaalien kanssa vaatimusten täyttämiseksi.

Tarvitsetko puristusjousia, vääntöjouset, pidennysjouset, tai langan muodot, Toimitamme mukautettuja ratkaisuja.

Suora tehdashinnoittelu varmistaa, että saat parhaan arvon ylimmälle laatulle.

Virtaviivaiset prosessit antavat meille mahdollisuuden toimittaa tilauksesi ajoissa, joka kerta.

Käsittelemme tehokkaasti kansainvälistä logistiikkaa toimittaaksemme kaikkialla maailmassa.

Jouset ovat laulamattomia sankareita monilla toimialoilla, Joustavuuden tarjoaminen, vahvuus, ja tarkkuus tarvitaan lukemattomiin sovelluksiin. Suunnittelitpa korkean suorituskyvyn koneet tai päivittäiset työkalut, Oikean materiaalin valitseminen varmistaa luotettavuuden, kestävyys, ja kustannustehokkuus. Havataan olennaiset asiat auttamaan sinua tekemään tietoisen päätöksen!

Kevään teräkset ovat uskomattoman suosittuja niiden joustavuuden vuoksi, vetolujuus, ja väsymysresistenssi. Ne ovat ihanteellisia sovelluksiin, joissa jouset ovat jatkuvan stressin tai kuorman alla.

Jos sovelluksesi sisältää altistumisen kosteudelle, kemikaalit, tai äärimmäinen sää, Ruostumaton teräs on sinun materiaali. Nämä seokset kestävät ruostetta ja varmistavat pitkäaikaisen suorituskyvyn.

Joskus, Hakemuksesi vaatii jotain ylimääräistä. Siellä erikoismateriaalit, kuten superseokset ja erittäin luja komposiitti.

Kotelo 1: Merilaitteiden valmistaja

Asiakassuunnittelujouset syvänmeren sovelluksiin valitsi 316Ruostumaton teräs sen ylivoimaisesta vastustuskyvystä suolavesikorroosiolle. Tämä päätös kaksinkertaisti heidän tuotteidensa käyttöikä ja alensi ylläpitokustannuksia 30%.

Kotelo 2: Raskas koneen rakentaja

Teollisuuspuristimien valmistaja vaihdettu SWP -seosteräs heidän jännitysjousistaan. Tulos? Jouset kestävät 20% korkeammat kuormat ja kesti 50% pidempi jatkuvan toiminnan alla.

Kotelo 3: Elintarvikkeiden jalostuksen käynnistys

Ruokaviipaleiden jousille, 304 ruostumaton teräs oli täydellinen valinta sen kohtuuhintaisuudesta ja elintarviketurvallisuusstandardien noudattamisesta. Käynnistys tallennettiin 15% kustannuksista samalla kun varmistetaan hygieninen suorituskyky.

| Sarja nro. | Teräsluokka | C (%) | Ja (%) | Mn (%) | Cr (%) | MO (%) | V (%) | B - (%) | Sisä- (%) | Cu (%) | P (%) | S (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 65 | 0.62–0.70 | 0.17–0.37 | 0.50–0.80 | ≤ 0.25 | - | - | - | 0.25 | 0.25 | ≤ 0.035 | ≤ 0.035 |

| 2 | 70 | 0.62–0.75 | 0.17–0.37 | 0.50–0.80 | ≤ 0.25 | - | - | - | 0.25 | 0.25 | ≤ 0.035 | ≤ 0.035 |

| 3 | 85 | 0.72–0.85 | 0.17–0.37 | 0.50–0.80 | ≤ 0.25 | - | - | - | 0.25 | 0.25 | ≤ 0.035 | ≤ 0.035 |

| 4 | 65Mn | 0.62–0.70 | 0.17–0.37 | 0.90–1.20 | ≤ 0.25 | - | - | - | 0.25 | 0.25 | ≤ 0.035 | ≤ 0.035 |

| 5 | 55SI2MN | 0.52–0.60 | 1.50–2.00 | 0.60–0.90 | ≤ 0.35 | - | - | - | 0.35 | 0.35 | ≤ 0.035 | ≤ 0.035 |

| 6 | 55To2mnb | 0.52–0.60 | 1.50–2.00 | 0.60–0.90 | ≤ 0.35 | - | - | 0.0005–0.004 | 0.35 | 0.35 | ≤ 0.035 | ≤ 0.035 |

| 7 | 55Si2mn jne. | 0.52–0.60 | 0.70–1.00 | 1.00–1.30 | ≤ 0.35 | - | 0.08–0.16 | 0.0005–0.0035 | 0.35 | 0.35 | ≤ 0.035 | ≤ 0.035 |

| 8 | 60SI2MN | 0.56–0.64 | 1.50–2.00 | 0.60–0.90 | ≤ 0.35 | - | - | - | 0.35 | 0.35 | ≤ 0.035 | ≤ 0.035 |

| 9 | 60Si2MNA | 0.56–0.64 | 1.60–2.00 | 0.60–0.90 | ≤ 0.35 | - | - | - | 0.35 | 0.35 | ≤ 0.035 | ≤ 0.030 |

| 10 | 60SI2CRA | 0.56–0.64 | 1.40–1.80 | 0.40–0.70 | 0.70–1.00 | - | - | - | 0.25 | 0.25 | ≤ 0.035 | ≤ 0.030 |

| 11 | 55Mato | 0.56–0.64 | 1.40–1.80 | 0.40–0.70 | 0.90–1.20 | - | 0.10–0.20 | - | 0.25 | 0.25 | ≤ 0.035 | ≤ 0.035 |

| 12 | 60Crmna | 0.56–0.64 | 0.17–0.37 | 0.70–1.00 | 0.70–1.00 | - | - | - | 0.25 | 0.35 | ≤ 0.035 | ≤ 0.035 |

| 13 | 50Mato | 0.46–0.54 | 0.17–0.37 | 0.50–0.80 | 0.80–1.10 | - | 0.10–0.20 | - | 0.25 | 0.25 | ≤ 0.035 | ≤ 0.035 |

| 14 | 30CVV2A | 0.26–0.34 | 0.17–0.37 | ≤ 0.40 | 2.00–2.50 | - | 0.50–0.80 | 4.4–5.0 | 0.35 | 0.35 | ≤ 0.035 | ≤ 0.035 |

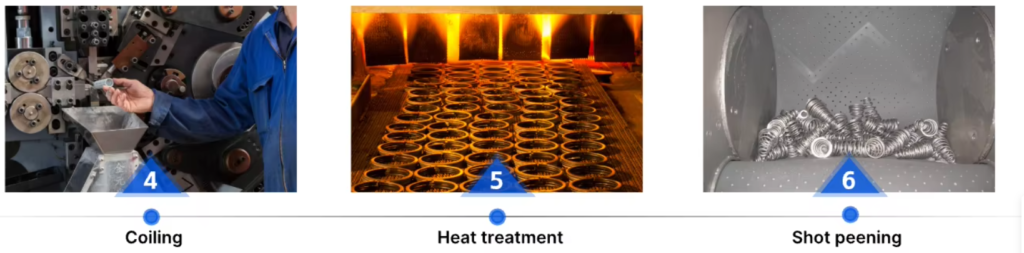

Jousilämpökäsittely on välttämätöntä mekaanisten ominaisuuksien optimoimiseksi, Kestävyyden varmistaminen, ja parantaa väsymiskestävyyttä. Erilaisia vahvistustekniikoita, kuten sammutus, karkaisu, ja pintakäsittelyt, käytetään materiaalityypin ja sovellusvaatimusten perusteella.

Jousien lämpökäsittelyprosessi voidaan luokitella kolmeen tyyppiin:

Sammutusprosessi varmistaa yhdenmukaisen martensiittisen muutoksen, seuraa karkaisu stressin lievittämiseksi ja sitkeyden parantamiseksi. Tekniikat, kuten isoterminen karkaisu, parantavat edelleen plastisuutta ja sitkeyttä, Jousen varmistaminen ylläpitää mittasarjaa ja mekaanista vakautta.

| Prosessityyppi | Kuvaus | Käytetyt materiaalit | Tärkeimmät vaikutukset |

|---|---|---|---|

| Sammutus & Karkaisu | Lämmitys AC3: n yläpuolella, pito, Sitten nopea jäähdytys ja karkaisu. | Hiilihiilinen teräs, seosteräs | Lisää voimaa, kovuus, ja joustavuus. |

| Kylmän työn vahvistaminen | Käyttää mekaanista muodonmuutoksia lämpökäsittelyn sijasta. | Ruostumattomasta teräksestä valmistettu lanka, kylmävalssatut teräsnauhat | Parantaa työvoimaa. |

| Ikääntymishoito | Lisälämpövakautus alkuperäisen prosessoinnin jälkeen. | Tietyt seosmateriaalit | Parantaa vakautta ja voimaa. |

| Isoterminen sammutus | Ylläpitää lämpötilaa MS: n yläpuolella, Jäähdyttää sulaa suolaa. | Hiilihiilinen teräs, kevytmetallijouset | Parantaa sitkeyttä ja plastisuutta. |

| Kontrolloitu karkaisu | Asteittainen jäähdytys muodonmuutoksen estämiseksi. | Tarkkuusjouset, mekaaniset komponentit | Vähentää sisäistä stressiä ja varmistaa tarkkuuden. |

Tämä jäsennelty lähestymistapa varmistaa, että jokainen lämpökäsittelymenetelmä on yhdenmukaistettu tietyille materiaalien ominaisuuksille ja sovellusvaatimuksille optimoidulle suorituskyvylle.

Jousien lämpökäsittely:

| Menetelmä | Prosessin kuvaus | Tärkeimmät edut | Yleiset sovellukset |

|---|---|---|---|

| Tavanomainen lämpökäsittely | Lämmitys ja jäähdytysteräs mekaanisten ominaisuuksien säätämiseksi | Lisää voimaa, joustavuus, ja kestävyys | Keskipitkästä ja hiilihiilinen teräsjouset |

| Pinnan kovettuminen | Hiihtäminen, nitroiva, tai ulkokerroksen induktion kovettuminen | Parantaa kulumiskestävyyttä pitäen samalla sitkeyttä | Auto- ja teollisuusjouset |

| Ikääntyminen & Karkaisu | Lämpökäsittely sisäisten rasitusten lievittämiseksi ja mikrorakenteen parantamiseksi | Parantaa vakautta ja mekaanista konsistenssia | Tarkkuus- ja korkean kuormitusjouset |

| Teräsluokka | Austenisoiva lämpötila (°C) | Isoterminen sammutuslämpötila (°C) | Jäähdytysaika (min) | Kovuus (HRC) |

|---|---|---|---|---|

| 65 | 820 ± 10 | 320 – 340 | 15 – 20 | 46 – 48 |

| 60Si2MNA | 870 ± 10 | 260 | 20 – 25 | 50 – 52 |

| 50Mato | 850 ± 10 | 300 | 20 – 25 | 55 – 57 |

| Terästyyppi | Lämpökäsittelyprosessi | Kovuus (HRC) | Vetolujuus (MPa) | Tuottovoima (MPa) | Pidentymä (%) | Iskusitkeys (J/cm²) |

|---|---|---|---|---|---|---|

| 50Mato | Perinteinen sammutus + Karkaisu | 48 | 1750 | 1500 | 10 | 44 |

| 60Si2MNA | Isoterminen sammutus + Karkaisu | 47 | 1900 | 1750 | 11 | 46 |

| 65Si2MnWA | Isoterminen sammutus + Karkaisu | 50 | 2100 | 1980 | 9 | 43 |

Tämä taulukkomuoto tarjoaa selkeän ja organisoidun vertailun erilaisista jousien lämpökäsittelytekniikoista.

Xiamen Linspring pystyi valmistamaan tilaukseni eritelmien mukaan ja oli avulias ja kommunikoi matkan varrella. Toimitetun tuotteen laatu oli hyvä.

Tämä oli toinen tilaukseni Linspringiltä. Myyjän kanssa on hyvä kommunikoida ja kevät oli täydellinen,aivan kuten ensimmäinen tilaus. Kiitos kehotuksestasi,kohtelias.

Erittäin tyytyväinen mukautettuihin jousiimme. Ajallaan ja toimitus oli nopea

Jouset ovat olennaisia komponentteja lukemattomilla teollisuudenaloilla, auto- ja ilmailuteollisuudesta lääkinnällisiin laitteisiin ja kodinkoneisiin. Mukautetut jouset, erityisesti, tarjota räätälöityjä ratkaisuja, jotka täyttävät erityiset suorituskykyvaatimukset, koko, materiaalia, ja sovellus. Mukautetun jousen suunnittelu vaatii useiden tekijöiden huolellista harkintaa, toimivuudesta ympäristöolosuhteisiin.

Puristusjouset

Jännitysjouset

Vääntöjouset

Flat Springs

Erikoisjouset

Oikean materiaalin valinta on kriittistä mukautetun jousen suorituskyvyn ja kestävyyden kannalta. Joitakin yleisiä materiaaleja ovat mm:

Hiiliteräs

Ruostumaton teräs

Seosteräs

Fosforipronssi ja berylliumkupari

Titaani

Inconel ja muut superseokset

Suunniteltaessa mukautettua jousta, on otettava huomioon useita tekijöitä:

Jousen tyyppi: Valitse sopiva jousityyppi (puristus, jännitystä, etc.) based on the application.

Kuormitusvaatimukset:

Kevään mitat:

Materiaalivalinta: Valitse materiaali, joka vastaa sovelluksen ympäristöä, vahvuus, ja kestävyysvaatimukset.

Stressi ja väsymys:

Toimintaympäristö:

Päätytyyppi:

Valmistusrajoitukset:

Define Your Requirements:

Choose a Material:

Work with LINSPRING:

Prototype Development:

Final Production:

Provide Clear Specifications:

Request Samples:

Keskustele vaatimustenmukaisuudesta:

Hyödynnä asiantuntemusta:

Suunnittele skaalautuvuus:

Mukautetut jouset ovat pelin vaihtajia tarkkuutta vaativiin sovelluksiin, suorituskykyä, ja luotettavuus. Ottamalla huolellisesti huomioon tekijät, kuten materiaali, design, ja toimintaympäristö, voit luoda tarpeisiisi täydellisesti sopivan jousen. Yhteistyö luotettavan valmistajan LIKE LINSPRINGin kanssa takaa saumattoman prosessin suunnittelusta tuotantoon, auttaa sinua saavuttamaan optimaaliset tulokset.

Etkö ole vielä varma, mikä materiaali sopii tarpeisiisi? Keskustellaan tietystä sovelluksestasi. Oli se sitten autoteollisuutta, ilmailu, tai tarkkuustekniikkaa, voimme auttaa sinua valitsemaan täydellisen materiaalin tarpeidesi mukaan.

Haluaisitko räätälöidyn suosituksen tai syvemmän sukelluksen johonkin materiaaliin? Tehdään projektistasi menestys!

Sähköposti: sales@linspring.net

Puhelin:+86-13599531763

Osoite: Yksikkö 502, kerros 5, Rakennus B, # 1 työpaja, Autoteollisuuden kaupungin osien tukikeskus (vaihe iv), Guankoun kaupunki, Jimein alue, Xiamen,Fujian,Kiina

Otamme sinuun yhteyttä sisällä 1 työpäivä.