Naši izvori su izrađeni za susret tačne specifikacije, Osiguravanje vrhunske performanse i pouzdanosti.

Od nehrđajućeg čelika do specijaliziranih legura, Radimo s raznim materijalima za ispunjavanje vaših zahtjeva.

Bilo da su vam potrebni kompresijski izvori, Torzijski izvori, Proširenje opruga, ili žičane oblike, isporučujemo prilagođene rješenja.

Direktne tvorničke cijene osigurava da dobijete najbolju vrijednost za kvalitetu vrhunskog nivoa.

Stjerovini procesi omogućavaju nam da dostavimo vaše narudžbe na vrijeme, svaki put.

Efikasno se obrađujemo međunarodnom logistikom da bismo dostavili bilo gdje u svijetu.

Opruge su neuobičajeni heroji u mnogim industrijama, Pružanje fleksibilnosti, snaga, i preciznost potrebna za bezbroj aplikacija. Bilo da dizajnirate mašine za visoke performanse ili svakodnevne alate, Odabir desnog materijala osigurava pouzdanost, izdržljivost, i isplativost. Razgradimo esencijance da vam pomognemo da napravite informiranu odluku!

Proljeće čelici su nevjerovatno popularni zbog njihove kombinacije elastičnosti, zatezna čvrstoća, i otpornost na umor. Idealni su za aplikacije u kojima su izvori pod stalnim stresom ili teretom.

Ako vaša aplikacija uključuje izlaganje vlazi, hemikalije, ili ekstremnim vremenskim prilikama, nehrđajući čelik je vaš omiljeni materijal. Ove legure su otporne na rđu i osiguravaju dugotrajne performanse.

Ponekad, vaša aplikacija zahtijeva nešto dodatno. Tu dolaze specijalni materijali poput superlegura i kompozita visoke čvrstoće.

Slučaj 1: Proizvođač morskih opreme

Opruge za dizajn klijenta za duboke morske aplikacije 316L Nerđajući čelik Za superiorniji otpor na koroziju slane vode. Ova odluka udvostručila je radni vijek svojih proizvoda i smanjio troškove održavanja od strane 30%.

Slučaj 2: Builder za teške mašine

Prebačen proizvođač industrijskih preše SWP legura čelika za njihove napetosti. Rezultat? Opruge sadrže 20% veća opterećenja i trajala 50% duže u kontinuiranom radu.

Slučaj 3: Pokretanje prehrane hrane

Za opruge u klizačima hrane, 304 nehrđajući čelik bio je savršen izbor zbog svoje pristupačnosti i poštivanja standarda sigurnosti hrane. Spremanje startapa 15% o troškovima, istovremeno osiguravajući higijenske performanse.

| Serijski br. | Čelična ocjena | C (%) | I (%) | MN (%) | CR (%) | Mo (%) | V (%) | B (%) | U (%) | Cu (%) | Str (%) | S (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 65 | 0.62-0.70 | 0.17-0.37 | 0.50-0.80 | ≤ 0.25 | - | - | - | 0.25 | 0.25 | ≤ 0.035 | ≤ 0.035 |

| 2 | 70 | 0.62-0,75 | 0.17-0.37 | 0.50-0.80 | ≤ 0.25 | - | - | - | 0.25 | 0.25 | ≤ 0.035 | ≤ 0.035 |

| 3 | 85 | 0.72-0,85 | 0.17-0.37 | 0.50-0.80 | ≤ 0.25 | - | - | - | 0.25 | 0.25 | ≤ 0.035 | ≤ 0.035 |

| 4 | 65MN | 0.62-0.70 | 0.17-0.37 | 0.90-1.20 | ≤ 0.25 | - | - | - | 0.25 | 0.25 | ≤ 0.035 | ≤ 0.035 |

| 5 | 55Si2mn | 0.52-0,60 | 1.50-2.00 | 0.60-0,90 | ≤ 0.35 | - | - | - | 0.35 | 0.35 | ≤ 0.035 | ≤ 0.035 |

| 6 | 55To2mnb | 0.52-0,60 | 1.50-2.00 | 0.60-0,90 | ≤ 0.35 | - | - | 0.0005-0.004 | 0.35 | 0.35 | ≤ 0.035 | ≤ 0.035 |

| 7 | 55Si2mn itd. | 0.52-0,60 | 0.70-1,00 | 1.00-1.30 | ≤ 0.35 | - | 0.08-0.16 | 0.0005-0.0035 | 0.35 | 0.35 | ≤ 0.035 | ≤ 0.035 |

| 8 | 60Si2mn | 0.56-0,64 | 1.50-2.00 | 0.60-0,90 | ≤ 0.35 | - | - | - | 0.35 | 0.35 | ≤ 0.035 | ≤ 0.035 |

| 9 | 60Si2mna | 0.56-0,64 | 1.60-2.00 | 0.60-0,90 | ≤ 0.35 | - | - | - | 0.35 | 0.35 | ≤ 0.035 | ≤ 0.030 |

| 10 | 60Si2cra | 0.56-0,64 | 1.40-1.80 | 0.40-0.70 | 0.70-1,00 | - | - | - | 0.25 | 0.25 | ≤ 0.035 | ≤ 0.030 |

| 11 | 55Crv | 0.56-0,64 | 1.40-1.80 | 0.40-0.70 | 0.90-1.20 | - | 0.10-0.20 | - | 0.25 | 0.25 | ≤ 0.035 | ≤ 0.035 |

| 12 | 60Crmna | 0.56-0,64 | 0.17-0.37 | 0.70-1,00 | 0.70-1,00 | - | - | - | 0.25 | 0.35 | ≤ 0.035 | ≤ 0.035 |

| 13 | 50Crv | 0.46-0.54 | 0.17-0.37 | 0.50-0.80 | 0.80-1.10 | - | 0.10-0.20 | - | 0.25 | 0.25 | ≤ 0.035 | ≤ 0.035 |

| 14 | 30Cvv2a | 0.26-0.34 | 0.17-0.37 | ≤ 0.40 | 2.00-2.50 | - | 0.50-0.80 | 4.4-5.0 | 0.35 | 0.35 | ≤ 0.035 | ≤ 0.035 |

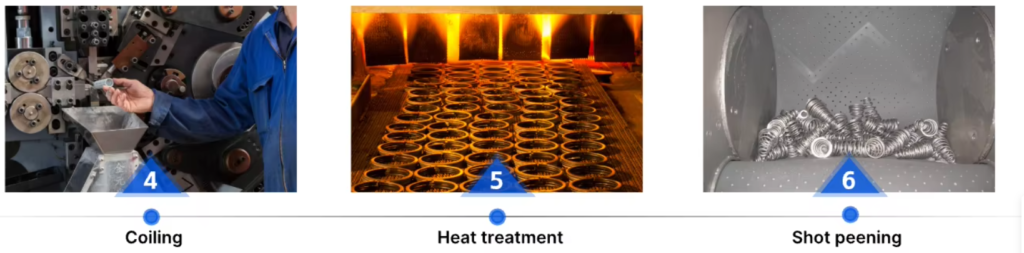

Proljetna toplotna obrada je neophodna za optimizaciju mehaničkih svojstava, Osiguravanje izdržljivosti, i poboljšanje otpornosti na umora. Razne tehnike jačanja, poput gašenja, kaljenje, i površinski tretmani, primjenjuju se na temelju tipa materijala i zahtjeva za primjenu.

Proces toplotnog obrade opruga može se kategorizirati u tri vrste:

Proces gašenja osigurava jednoliku martenzitnu transformaciju, praćeno kaljenjem za ublažavanje stresa i poboljšati žilavost. Tehnike kao što je izotermno kaljenje dodatno poboljšavaju plastičnost i žilavost, osiguravajući da opruga održava točnost dimenzija i mehaničku stabilnost.

| Vrsta procesa | Opis | Korišteni materijali | Ključni efekti |

|---|---|---|---|

| Gašenje & Kaljenje | Grijanje iznad Ac3, holding, zatim brzo hlađenje i kaljenje. | Visokougljični čelik, legirani čelik | Povećava snagu, tvrdoća, i elastičnost. |

| Jačanje hladnog rada | Koristi mehaničku deformaciju umjesto toplinske obrade. | Žica od nerđajućeg čelika, hladno valjane čelične trake | Poboljšava svojstva učvršćivanja pri radu. |

| Tretman starenja | Dodatna stabilizacija topline nakon početne obrade. | Određeni legirani materijali | Poboljšava stabilnost i snagu. |

| Izotermno gašenje | Održava temperaturu iznad Ms, hladi u rastopljenoj soli. | Visokougljični čelik, legure opruge | Povećava čvrstoću i plastičnost. |

| Kontrolirano kaljenje | Postepeno hlađenje kako bi se spriječile deformacije. | Precizne opruge, mehaničke komponente | Smanjuje unutrašnji stres i osigurava preciznost. |

Ovaj strukturirani pristup osigurava da je svaka metoda toplinske obrade usklađena sa specifičnim svojstvima materijala i zahtjevima primjene za optimizirane performanse.

Termička obrada izvora:

| Metoda | Opis procesa | Ključne prednosti | Uobičajene aplikacije |

|---|---|---|---|

| Konvencionalna toplinska obrada | Grijanje i hlađenje čelika za podešavanje mehaničkih svojstava | Povećava snagu, elastičnost, i trajnost | Opruge od srednjeg do visokougljičnog čelika |

| Obrada površinskog očvršćavanja | Carburizing, nitriranje, ili indukcijsko stvrdnjavanje vanjskog sloja | Povećava otpornost na habanje uz zadržavanje žilavosti jezgra | Automobilske i industrijske opruge |

| Starenje & Kaljenje | Toplinska obrada za ublažavanje unutrašnjih naprezanja i pročišćavanje mikrostrukture | Poboljšava stabilnost i mehaničku konzistenciju | Precizne opruge i opruge visokog opterećenja |

| Čelična ocjena | Austenitizing Temperature (°C) | Isothermal Quenching Temperature (°C) | Cooling Time (min) | Hardness (HRC) |

|---|---|---|---|---|

| 65 | 820 ± 10 | 320 – 340 | 15 – 20 | 46 – 48 |

| 60Si2mna | 870 ± 10 | 260 | 20 – 25 | 50 – 52 |

| 50Crv | 850 ± 10 | 300 | 20 – 25 | 55 – 57 |

| Steel Type | Heat Treatment Process | Hardness (HRC) | Zatezna čvrstoća (MPa) | Yield Strength (MPa) | Elongation (%) | Impact Toughness (J/cm²) |

|---|---|---|---|---|---|---|

| 50Crv | Conventional Quenching + Kaljenje | 48 | 1750 | 1500 | 10 | 44 |

| 60Si2mna | Izotermno gašenje + Kaljenje | 47 | 1900 | 1750 | 11 | 46 |

| 65Si2MnWA | Izotermno gašenje + Kaljenje | 50 | 2100 | 1980 | 9 | 43 |

This table format provides a clear and organized comparison of different heat treatment techniques for springs.

Xiamen Linspring was able to manufacture my custom order to specifications and was helpful and communicatie along the way.The quality of the delivered product was good.

This was my second order with Linspring. The seller is great to communicate with and the spring were perfect,just like the first order. Thank you for your prompt,courteous.

Veoma zadovoljan našim prilagođenim izvorima. Na vrijeme i dostava je bila brza

Opruge su bitne komponente u bezbroj industrija, Od automobilskog i zrakoplovnog do medicinskih uređaja i kućanskih aparata. Prilagođeni izvori, posebno, nude prilagođena rješenja za ispunjavanje specifičnih zahtjeva za performanse, veličina, materijal, i primjena. Projektiranje prilagođenog proljeća zahtijeva pažljivo razmatranje brojnih faktora, iz funkcionalnosti do okoliša.

Kompresioni

Tension Springs

Torzijski izvori

Flat Springs

Specialty Springs

Odabir pravog materijala je ključan za performanse i izdržljivost prilagođene opruge. Neki uobičajeni materijali uključuju:

Carbon Steel

nerđajući čelik

Legura čelika

Brončani i berilijev bakar sa fosforom

Titanijum

Inconel i drugi superomasi

Prilikom dizajniranja prilagođenog proljeća, Postoji nekoliko faktora za razmatranje:

Proljetni tip: Odaberite odgovarajuću vrstu proljeće (kompresija, napetost, itd.) Na osnovu aplikacije.

Zahtevi za opterećenje:

Dimenzije opruge:

Odabir materijala: Odaberite materijal koji odgovara okolišu aplikacije, snaga, i zahtjevi za trajnost.

Stres i umor:

Operativno okruženje:

End Type:

Manufacturing Constraints:

Definirajte svoje zahtjeve:

Odaberite materijal:

Radite sa LINSPRING-om:

Razvoj prototipa:

Finalna produkcija:

Navedite jasne specifikacije:

Zatražite uzorke:

Razgovarajte o usklađenosti:

Leverage Expertise:

Plan za skalabilnost:

Prilagođene opruge mijenjaju igru za aplikacije koje zahtijevaju preciznost, performans, i pouzdanost. Pažljivim razmatranjem faktora kao što je materijal, dizajn, i radno okruženje, možete kreirati oprugu koja savršeno odgovara vašim potrebama. Partnerstvo s pouzdanim proizvođačem LIKE LINSPRING osigurava besprijekoran proces od dizajna do proizvodnje, pomaže vam da postignete optimalne rezultate.

Još uvijek niste sigurni koji materijal odgovara vašim potrebama? Razgovarajmo o vašoj konkretnoj aplikaciji. Bilo da je to automobil, vazduhoplovstvo, ili precizni inženjering, Možemo vam pomoći da odaberete savršen materijal prilagođen vašim potrebama.

Želite li prilagođenu preporuku ili dublji zaroniti u jedan od materijala? Napravimo vaš projekt uspjeh!

Email: sales@linspring.net

Telefon:+86-13599531763

Adresa: Jedinica 502, kat 5, Zgrada B, # 1 radionica, Centar za podršku gradskim dijelovima auto industrije (faza iv), Guankou Town, Jimei District, Xiamen,Fujian,Kina

Kontaktiraćemo vas u roku 1 radni dan.